RRD HYDROFOIL

COLLECTION

OUR HYDROFOIL MASTS: CONSIDERING THE MAST IS THE SPINE OF THE HYDROFOIL BODY,

THIS YEAR WE FOCUSED ON A TOTAL REDESIGN OF THE RANGE.

TWO ARE THE FACTORS WHERE WE HAVE BEEN CONCENTRATING OUR WORK:

LATERAL AND TORSIONAL STIFFNESS (FLEX AND TWIST) OF THE MAST.

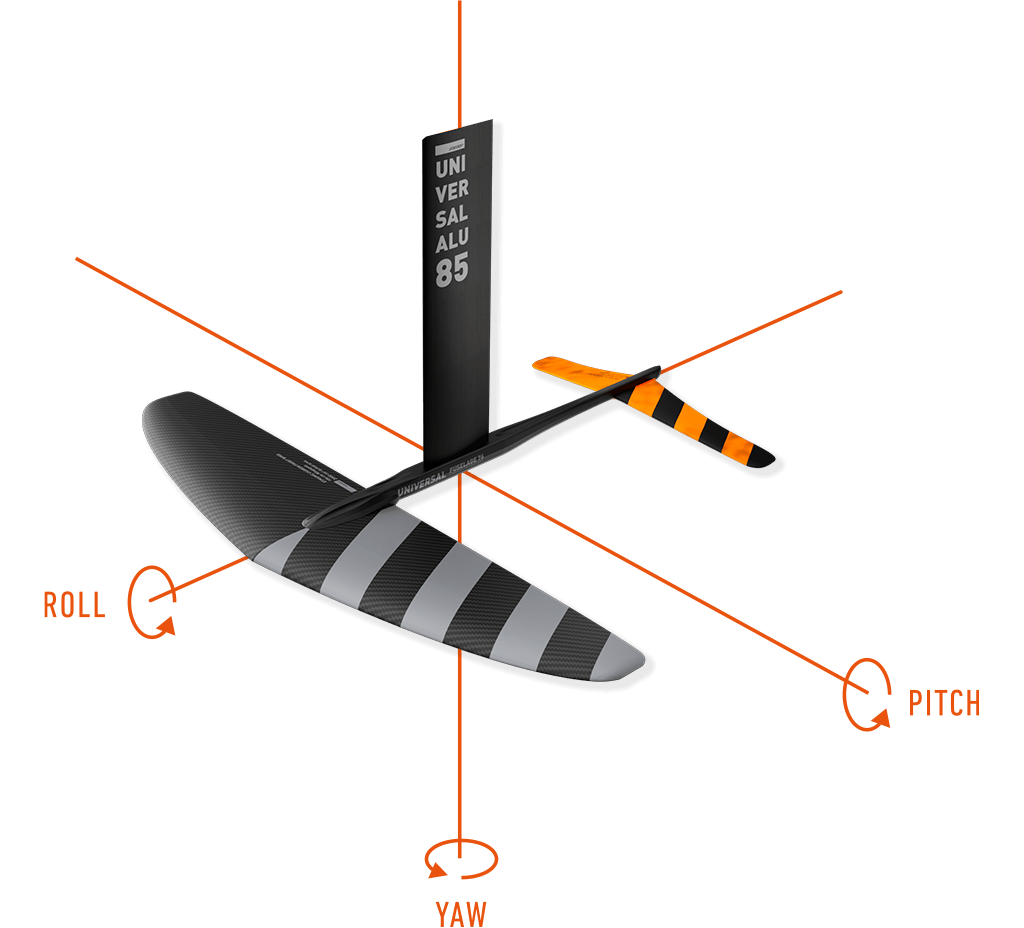

Controlling the flex of a mast means to better control the “roll” of the foil. If a foil rolls easily, it is hard to control and the foil becomes very nervous and unstable to ride. Controlling the roll of the foil through a lower flex of the mast is by far the most important improvement on our foils this year to allow extra stability and a comfortable and secure feel.

Until recently the effects of Yaw on the hydrofoil have been largely underestimated. The Yaw is the twisting/rotational force applied to the mast whilst riding the hydrofoil. This twisting creates a side drag of the foil that depending on the speed of the foil, can quickly lead to a complete loss of control. This is the most important feature on a hydrofoil mast to allow better average and top end speed.

Once the mast is attached to the wall, we measure its distance to a bar placed parallel to the mast. Then we attach a 30 kgs weight to the end of the mast and measure the new distance from the bar. The difference is the SIDE FLEX.

A higher distance number will indicate a mast with lower lateral stiffness (softer mast to side pressure).

Once the mast is equipped with its fuselage and is attached to the wall, we lock the fuselage aligned with the line of the leading edge of the mast, so it cannot bend towards the floor when under pressure. Then we apply a load by attaching a 30 kgs weight on the rear part of fuselage at 36 cms from the middle line of the mast. The measurement is taken from the floor and the difference between the loaded fuselage and the unloaded fuselage is the Mast Twist measurement.

A higher number will indicate a higher twist (lower torsional stiffness).

In order to increase both lateral and torsional stiffness of the ALU mast, we have redesigned a new mast profile and mould. The new mast now has a maximum thickness of 18mm and its profile is also proportionally thicker towards the trailing edge in order to minimise twist. We have also introduced a new middle stringer structure in between the two screws that have allowed a higher lateral stiffness. The incorporated top plate is smaller and shorter than the Y25 UNIVERSAL ALU MAST resulting in a lighter weight. The new ALU mast has an unparalleled TWIST of only 2,2 cms, feeling as torsional stiff as a full hi-modulus M40J Carbon mast !!!